Our Approach

Generate results in days and weeks, instead of months and quarters.

Our lean process improvement consulting approach leverages speed in assessment and implementation to help you quickly take advantage of your greatest opportunities for improvement. Our consultants bring to the table decades of experience in c-suite, operational leadership, and continuous improvement roles that translate into a bias for action. We work hands on, alongside your team at the point of impact, to generate immediate results, build momentum, and stack up the gains.

Quantify Improvement Priorities

A comprehensive operational diagnostic identifies the gaps between your current state and world class performance. We dig deep and do it quickly—usually within two weeks per location. Pre-work and onsite analysis cover seven critical performance dimensions—leadership, asset condition, lean maturity, management system, S&OP, quality, and automation.

Your final report outlines current year and run rate savings and financial impact by improvement theme. We provide a go forward recommendations and a detailed implementation plan complete the picture, and get to work capturing your full potential immediately.

Hands-On Support with Clear Impact

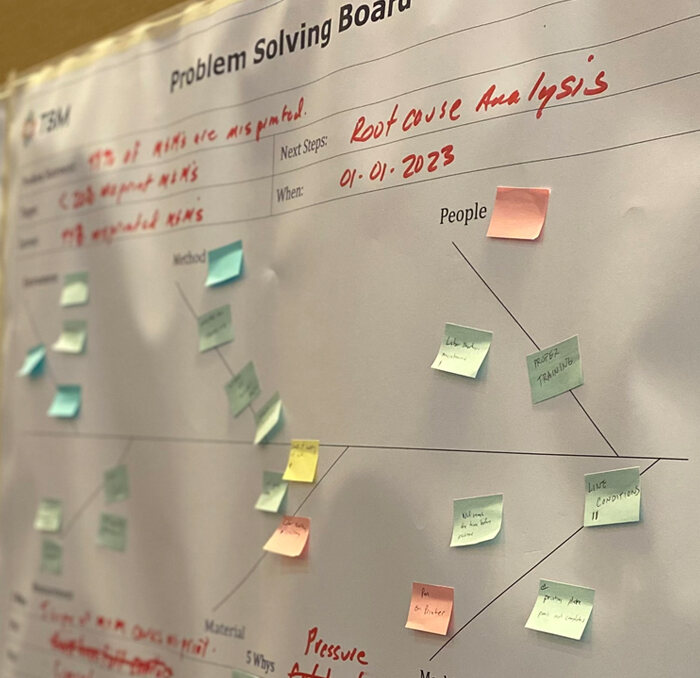

The point of impact—where products are made or services are rendered—is where value is created. This is where TBM works, shoulder-to-shoulder with your team, applying tools and methodologies to solve business problems in the shortest timeframe. We draw upon a full battery of lean tools, analytics, enabling technologies, embedded resources, coaching, and training to drive improvement, engage employees, and sustain gains.

From enterprise-wide transformations, site-specific engagements to targeted improvement projects, we work onsite with your team short or long term. Either way, you won’t wait to see impact. The gains happen fast, and we help you measure progress along the way.

Visibility. Accountability. Action.

The work you do with TBM is and you can expect rapid, measurable results and a disciplined process for sustainment. We align and link improvement initiatives to your breakthrough objectives, annual operating plan, and daily, weekly, and monthly KPIs, so everyone sees progress and benefits.

We insist on a steering committee and regular reviews not only to monitor results but also to keep projects on track and remove obstacles throughout the engagement.

Framework and Structure for Success

Improvement is addictive. Once you start, you won’t want to stop. The TBM Management System is our most effective tool for ensuring your long-term sustainable growth and profitability. The system equips you with an integrated set of processes and tools to connect strategy with annual objectives, translate vision into operational actions, and monitor and improve the effectiveness of your work both in and on the business.

We teach you how to win the day, the week, month and year. Winning becomes second nature.

Create Internal Experts

From the top floor to the shop floor, every member of your team has a critical role to play in making and sustaining gains. Our consultants work side-by-side with people at all levels to build skills for execution and sustainment. We leave behind playbooks and customized training materials. And we offer experiential awareness training as well as dedicated onsite workshops for Lean Certification, as well as LeanSigma Green Belt and Black Belt training.

Create the operational muscle to maintain your continuous improvement culture long-term.

Expect high-impact results.

When you have engaged and knowledgeable people, following proven process rigor and supported by the right technologies, your business will be in the best possible position to achieve operational excellence and its full growth potential.